Experience

Heineken México

Cervecería Cuauhtémoc Moctezuma

3D Printing is a permanent endeavor by Heineken Global because it allows for parts that are cheaper and faster to obtain, as well as tailored to specific engineering needs.

From March 2023 to March 2024, I was in charge of the 3D Printing efforts of Heineken’s Monterrey Plant. Using mainly Autodesk Fusion 360, I reversed engineered multiple OEM parts such as axle end caps or spray nozzle pipe clamps. Additionally, I led the design of original parts that have been used for different purposes, making use of diverse materials ranging from the typical PLA to more specialized ones such as CPE+ (improved co-polyester) and TPU 95A (thermoplastic polyurethane).

With two UltiMaker S5 printers, I managed part production to achieve more than two and a half million Mexican pesos as savings for the company in a year.

Below, you can find some of the designs I developed during my internship.

My designs are up and running.

A glimpse into the future.

I have had hand-in-hand experience with top-of-the-line 3D scanning devices by Scantech, Artec 3D, and Shining 3D. Using laser rays, these scanners are able to capture hundreds of thousands of points, locating them in three-dimensional space.

This can make the reverse engineering process faster and more reliable, especially when using specialized software such as Geomagic Design X. At Heineken Monterrey, we are considering to acquire a 3D scanner to keep the company at the frontline of additive manufacturing technology.

Other experiences

Product Development Engineer: Freezo

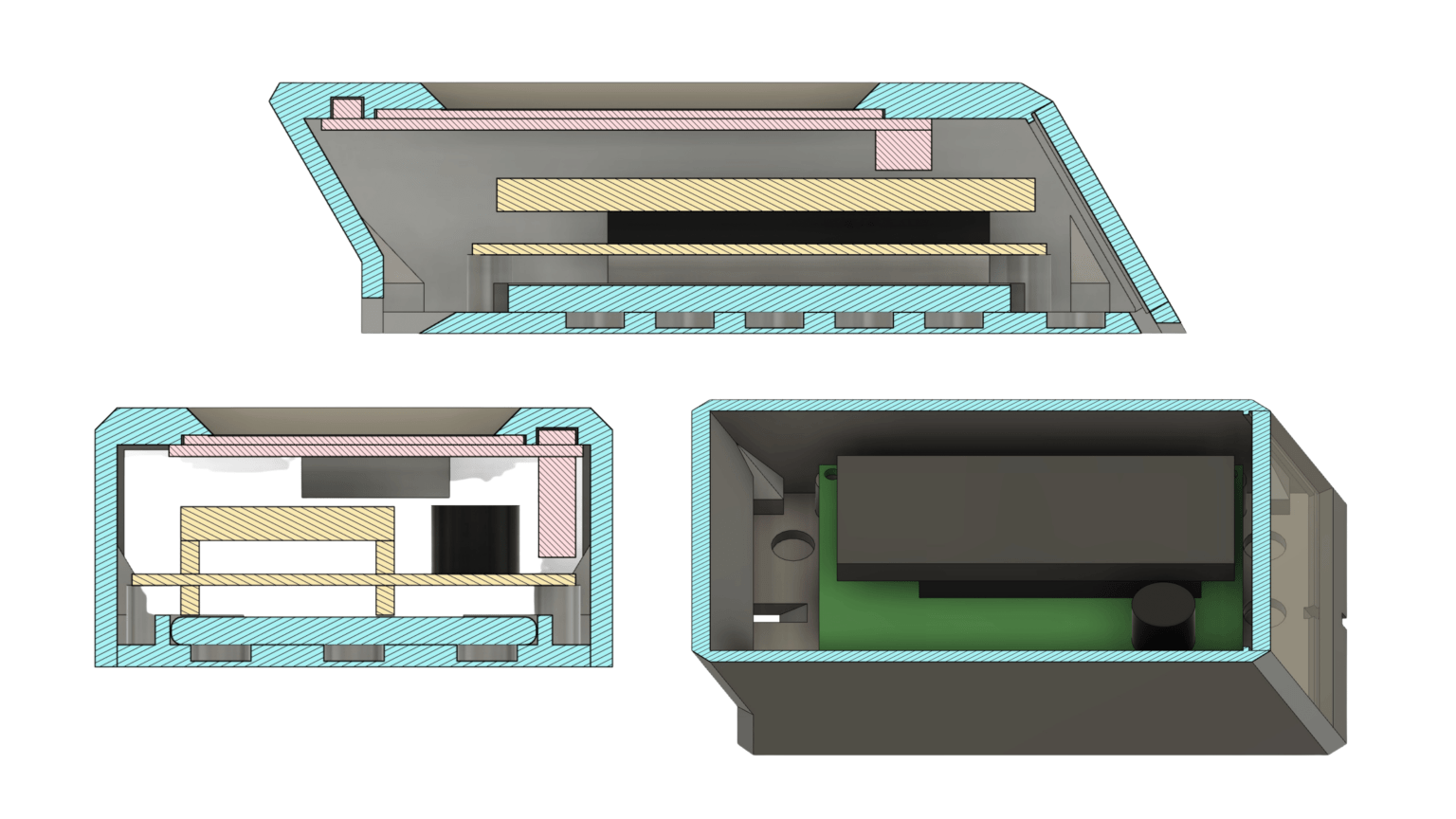

Development of Freezo, a smart thermometer for refrigeration systems.

The project involved opportunity and needs identification, both on client and user side, and agile product development overall using Scrum. I led mechanical design of the enclosure and internal fastenings for the electronic components, oriented for 3D printing.

Innovation Consultant: Questum Mobility

After intensive research, I worked on a proposal of an innovation project portfolio prioritized by technological horizons. Questum Mobility is a company based in Nuevo León, pioneering electric conversion for cargo trucks, with important multinational clients in the country. Technology monitoring (S-curves, tech cycles) & roadmapping were included. For privacy reasons, the specific projects cannot be shared.